At Lemtapes, we’re constantly striving to develop and offer innovative tapes and adhesives solutions while reducing material consumption and environmental impact. Our products strengthen cardboard packaging and make opening easier.

Our reinforcement tapes offer customers significant material savings, because they then need less material to manufacture their cardboard packaging. The result? Light and durable packaging that protects the inner product better throughout storage, transport and delivery.

Slim Tape improves production efficiency and packaging design for Adara Pakkaus

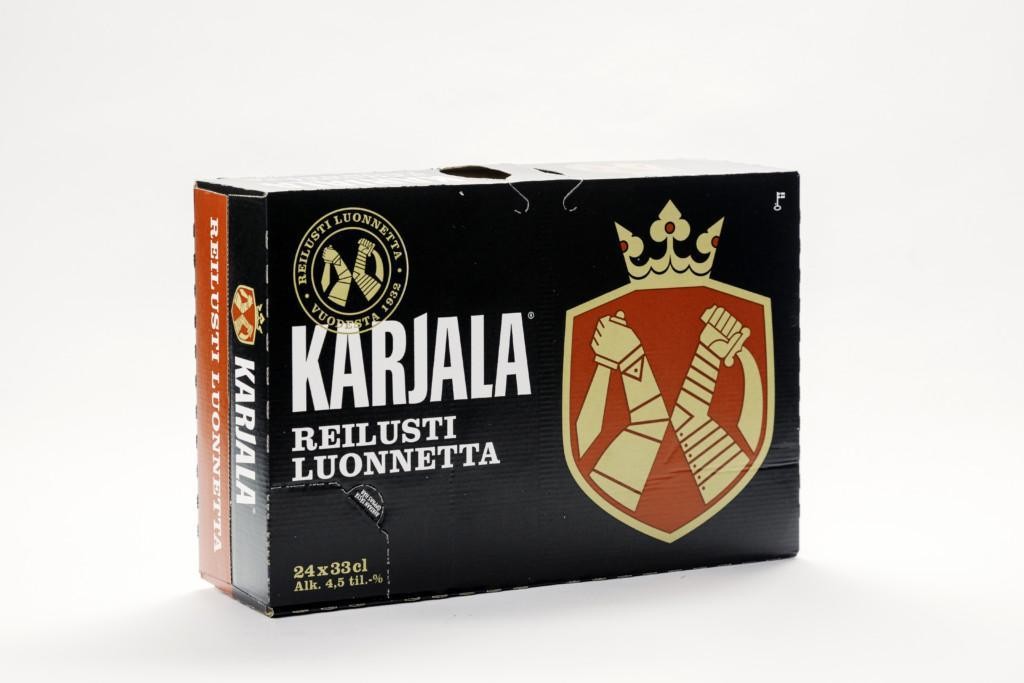

We’ve recently brought a new, thinner version of reinforcement tape to the market. We’re calling it ‘Lemtapes Slim Tape’, and it offered Adara Pakkaus, a Finnish packaging manufacturer, a solution to reduce the high production costs of the Karjala beer multipack box. With the help of this new reinforcement tape, Adara’s paper usage dropped by 23 percent:

- Liner start grammage 130 g/m2, total paper grammage 390 g/m2

- Achieved grammage 90 g/m2, total paper grammage 300 g/m2

This result was in line with the cost-saving structure we presented for Slim Tape at the FEFCO Technical Seminar in 2019.

For the Karjala multipack carrying handle, we developed an even thinner reinforcement tape. Its tensile strength matches ordinary reinforcement tape, but enables a 22% thinner reinforcement material, from 0.27mm to 0.21mm.

In addition to durability, consumer friendliness in packaging manufacturing is something that’s always at the top of our minds. Even large cardboard packaging should be functional and attractive, both from the perspective of transport and the end consumer. For this reason, the importance of packaging design, print quality and color has grown in the industry — and we’ve stayed at the forefront of these developments.

Adara Pakkaus Oy’s challenge was to produce visually appealing packaging that was durable enough to withstand warehousing and transport. Slim Tape was developed to meet this growing demand.

The thinner tape enables high quality printing on cardboard packaging, making it possible to achieve a more distinctive and memorable brand image. This offers more options overall for developing unique and distinctive packaging, both in design and implementation.

Our commitment to sustainability

For us, it’s critical to make sure our customers have an ecological solution for their packaging challenges, and we emphasise environmental sustainability throughout our product development. All of our tapes are available as cellulose-based Pure Tape, which won the FEFCO Sustainability Award in Geneva, Switzerland in 2019.

Our Pure Tape innovation replaces the plastic fibres previously used in the reinforcement tapes of corrugated cardboard packaging. Aiming to be entirely biodegradable, we’ve chosen cellulose as Pure Tape’s primary raw material – and 75% of Pure Tape in total is composed of organic material.

We developed Pure Tape alongside Eco Tape, another environmentally friendly tape. Eco Tape is composed entirely of recycled material and can be used as a reinforcement tape or opening tape. In terms of functionality, it is identical to Lemtapes Carton Tape.

Aside from ecological tapes, we’ve designed several other products to benefit the packaging industry, such as Open Tape, that work together to offer a frustration-free customer experience.